Comparing COB Chip Technologies: Wire-Bonded and Flip-Chip Structures

LED packaging technology has undergone a revolutionary shift with developments in chip-on-board (COB) technology, and the two common chip structures are the traditional wire-bonded (face-up) chip and the newer flip-chip structure. Both technologies have different advantages and disadvantages, but each is optimal for a specific application.

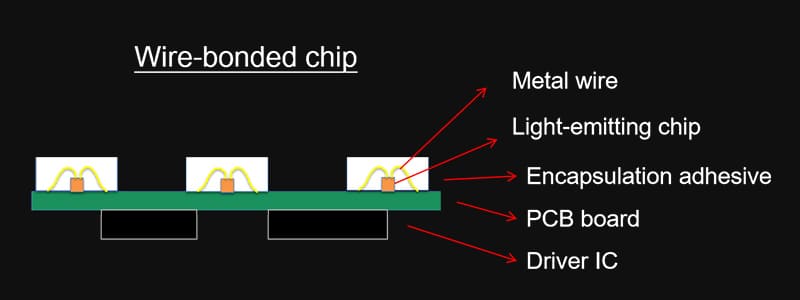

Wire-Bonded COB Technology

The face-up chip wire-bonded configuration is the longest and most widespread low-power LED application. The configuration consists of an upper electrode, then P-GaN layers, emitting layer, N-GaN, and finally the substrate.

Advantages:

· Standardized Manufacturing Process: Having a standardized equipment and process to manufacture it, the production process has high yields coupled with standard quality.

· Secure Bonding: Wire bonding provides secure and standardized electric bonding.

· Cost-Effective: Low chip cost makes this technology an affordable price advantage.

Limitations:

· Increased Power Consumption: Lateral current distribution leads to congestion during high current conditions.

· Decreased Brightness: The top-side electrode will darken and thus reduce luminous efficiency.

· Poor Heat Spreading: Die mounting with insulating adhesive results in impaired thermal conductivity.

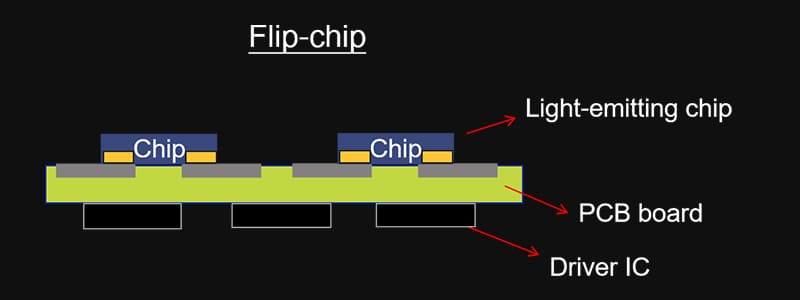

Flip-Chip COB Technology

Flip-chip technology is associated with a more advanced technique, where the build-up includes a substrate, an N-type GaN layer, multiple quantum wells (MQWs) for emission, a P-type GaN layer, and metal electrodes and solder bumps. The method is further divided into two categories: one with retention of the substrate for improved heat dissipation and one without substrate removal for the realization of increased current density and electrical performance.

Advantages

· Increased Production Efficiency & Lower Costs: Decreases the wire bonding process, streamlines production, and increases yield levels.

· Lower Design & Higher Integration: With wire-free eutectic bonding, pixel space is reduced, and package size can be minimized by as much as 80% and the wire-bonded chip spacing limitations overcome.

· Enhanced Reliability: Flip-chip COB replaces wire bonding with metal bonding surfaces, removing defects like open circuits and sub-standard solder joints, going a long way in enhancing lifespan.

· Increased Luminous Efficiency: Since both electrodes share the same side, the luminous surface area is much larger compared to wire-bonded assemblies.

· Increased Heat Dissipation: Direct electrode bump bonding to the substrate minimizes the distance by which heat must be transferred, leading to improved thermal control.

· Wider Viewing Angles: A top free from obstruction allows five-sided light extraction for improved visual performance.

· Improved Color Quality: Reduced operating currents and improved heat dissipation reduce color shift with heating.

· Improved Seamless Splicing: Wire bonding eliminated reduces encapsulation thickness such that no seams or brightness gradations are visible between modules, permitting wider close-up visibility.

· Improved Contrast: Reduced fill factor of light source produces more contrast enhancement at the same brightness.

· Cost Savings: Simplified manufacturing without wire bonding saves total manufacturing cost.

Limitations:

· Decreased Yield Rates: Higher expense of flip-chip technology demands 2-3 times more manufacturing than wire-bonded chips.

Milestrong's MCOB Series utilizes flip-chip technology to take advantage of its outstanding heat dissipation, high integration density, and seamless splicing to offer a future LED display solution. In the future, mature flip-chip COB will definitely be one of the driving forces for the development of high-performance LED applications.

Despite wire-bonded COB technology being a tried-and-true solution for mid-to-low power devices, flip-chip COB technology offers unprecedented brightness levels, thermal capabilities, durability, and display capabilities. As manufacturing technology improves, flip-chip technology will increasingly become the go-to option for high-end LED displays.