Exploring What IMD LED Display Technology Is and Why It's a Wiser Choice for Fine Pixel Pitch Applications

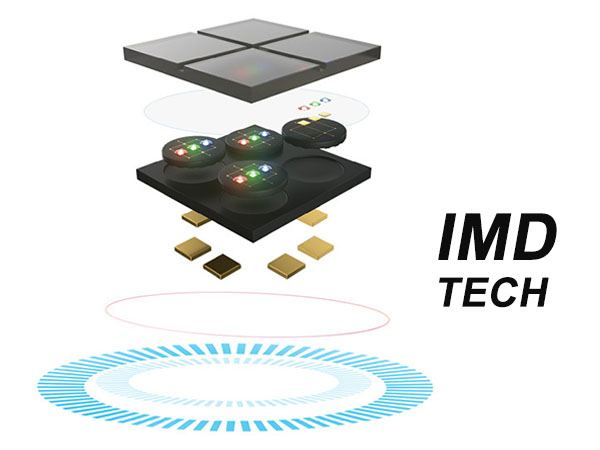

IMD (Integrated Matrix Device) LED displays is an important midstream packaging innovation in the realm of LEDs. By applying four-in-one technology, IMD packages encapsulate four basic pixel structures in a single encapsulated unit, with each consisting of 12 RGB LED chips. This package is also referred to as "four-in-one" or alternatively IMD. By integrating the advantage of both COB technology and SMD discrete components, IMD LED displays well address problems such as collision resistance, overall stability, color homogeneity, splicing gaps, light leakage, and maintenance difficulty. IMD hence becomes a balanced and viable option in progress toward achieving smaller pixel pitches.

IMD displays offer good uniformity on the screen, performing significantly better than COB. Their impact resistance is also enhanced; compared to conventional SMD LEDs, IMD modules contain a higher number of soldering pads per light and are hence four times more resistant to impacts. This facilitates easier resolution of issues like lamp drop-offs at rental events in the past. In terms of maintenance, IMD is way better than COB because separate LED lights may be repaired individually, saving costs while maintaining color and appearance consistency.

From a production point of view, IMD technology is highly cost-efficient. Its manufacturing process is also identical to that of traditional SMD devices, allowing manufacturers to use existing 1010 production lines without major investments in new machinery. The four-in-one structure of IMD also implies fewer solder joints, reducing the risk of failure from poor connections. Additionally, in contrast to SMD, IMD requires only one placement action instead of four, greatly improving production efficiency.

However, IMD LED displays have their own set of limitations. They offer lower adjustable pixel pitch and a considerably high initial cost of investment in customized pitches. IMD also is not ideal for large pixel pitch designs and use outdoors and enjoys a worse price-performance ratio relative to typical SMD in some projects. Further, like SMD, IMD has physical constraints on reducing the pixel size. Owing to several RGB chips randomly soldered within one unit, perfect color consistency after packaging may be more difficult to attain with IMD LED displays than with conventional discrete components.

In summary, IMD LED displays present a very attractive mix of high integration, robustness, maintenance simplicity, and cost effectiveness and are a good compromise for future fine-pitch LED applications.