Led Display COB And GOB Difference

Led Display COB And GOB Difference

Differences between COB and GOB packaging processes and their effects on LED stability

With the progress of science and technology, LED display has occupied an increasingly important position in our daily life. The traditional SMD labeling process, however, how to ensure the stability of LED lamp beads, to prevent the phenomenon of lamp drop, has been the focus of the industry. In this problem, the two packaging processes of COB and GOB play a key role. This article will explore the differences between these two packaging processes and their impact on LED stability.

First, let's look at COB packaging. COB packaging, or Chip on Board, is a packaging technology that binds the LED chip directly to the circuit board. Because the chip is attached directly to the circuit board, the surface of the COB package is very flat. In addition, the COB package also has a certain degree of protection, which can effectively prevent the damage of the external environment to the LED chip. However, despite these advantages of COB packaging, the thermal performance and stability of COB packaging still need to be improved due to its structure.

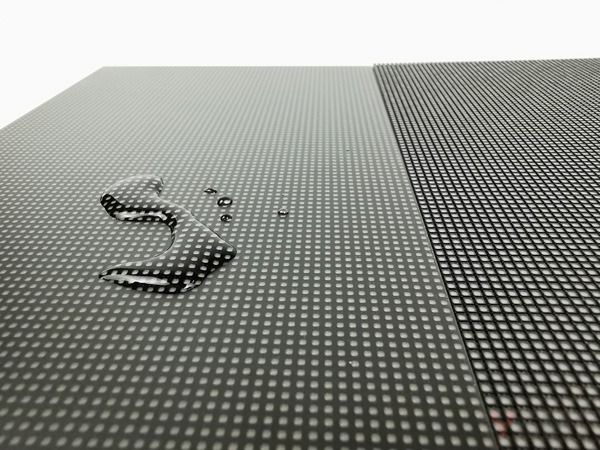

Compared with COB package, GOB package has a further improvement in the process. The GOB package adds a layer of glue on the surface of the LED chip, which not only improves the heat dissipation performance of the LED, but also greatly enhances the stability of the LED. The presence of glue can absorb external vibration and prevent the LED chip from falling off due to vibration. In addition, the glue can also provide better protection for the LED chip, so that it can better resist the infringement of the external environment. Therefore, compared with COB package, GOB package performs better in terms of stability.

In general, COB packaging and GOB packaging have their own advantages in terms of process and stability. The COB package has a flat surface and a certain degree of protection, while the GOB package is better in terms of heat dissipation performance and stability. In order to improve the quality and stability of LED products, the industry has begun to widely adopt GOB packaging technology. In the future, with the continuous development of science and technology, we look forward to more innovative packaging technology to bring greater breakthroughs and development for the LED industry.

About Milestrong Service

About Milestrong Service Milestrong Display Co. Ltd. customizes various types of LED digital display, Flexible LED Screen,Interactive LED Floors,Holographic LED Screen ,Immersive LED Displays,creative LED displays etc,our company has a relatively complete production chain and professional technicians, engaged in indoor and outdoor and other display production. After obtaining the design scheme from the customer, we provide one-stop service, customize the finished product of the scheme, deliver it to the customer, and provide good after-sales service

If you want to know more details about sphere led display, please do not hesitate to contact us! Be sure to follow us on LinkedIn and Youtube channel to get the latest news, information and all our new technology solutions

- Previous Article:Advantages And Disadvantages Of COB Technology

- Next Article:What Is An Ultralight Outdoor LED Screen?