Advantages and Disadvantages of High Quality LED Display Screen with COB Encapsulation Technology

LED display encapsulation technology has always been a very concerned issue, especially COB packaging technology, from the advantages and disadvantages of COB packaging technology to learn it.

Advantages:

Good display effect: COB is an integrated package, uniform light, approximate surface light source, the picture is softer than SMD and IMD, and the viewing comfort is higher, in addition, the use of flip-chip COB light source area is lower, which can significantly improve the contrast and display better.

Smaller pixel pitch: Without the diameter of a single lamp body, the spacing can be smaller.

High contrast: No lamp cup and stand, smaller monomer pixels, higher colloidal coverage.

Reduction process flow: COB does not need SMD patch and reflow process, greatly improve the stability, can effectively avoid the traditional SMD package more and more defects, reduce the support, simplify the manufacturing process, and reduce the manufacturing cost.

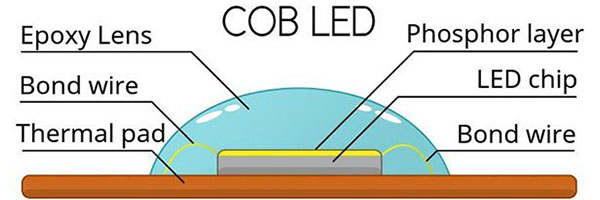

Anti-collision and anti-pressure: COB products are directly packaged in the concave lamp position of the PCB board, and then cured with epoxy resin adhesive packaging, smooth and hard, crash-resistant and wear-resistant.

Wear-resistant, easy to clean: there is no mask on the surface, the screen body is smooth and hard, crash-resistant and wear-resistant, and dust can be cleaned with water or cloth.

Strong heat dissipation: The COB product is to package the chip on the PCB board, and quickly transfer the heat of the wick through the copper foil on the PCB board.

Low failure rate: the failure rate of SMD is 1/10,000, that is, 100PPM, COB is 10-30PPM, and the failure rate is 2-3 times that of SMD.

High reliability: COB products directly package the LED chip in the concave lamp position of the PCB board, and then use epoxy resin adhesive encapsulation and solidified, the chip and welding foot are wrapped in sealant, the air tightness is better smooth and hard, crash-resistant and wear-resistant, can withstand further improvement of thrust, and the surface is smooth and seamless, not easy to attach harmful substances, with moisture, anti-static, anti-bump, dust and other functions. The surface protection level reaches IP65, avoiding the problem of dead and broken lights caused by humidity, static electricity, dust and other environmental factors of SMD package small-pitch LED.

Weaknesses:

Splicing: Splicing caused by module accuracy and splicing caused by colloid stress thermal expansion and contraction.

Low yield: The pass rate of good products in COB unit is >70%, and the yield of pixels is >99.95%, mainly due to the consistency of operation of transfer process, welding process and solder paste at different use times.

Low production efficiency: The pixel pitch becomes smaller, the number of chips is doubled, the workload that needs to be transferred is very large, and the current mainstream transfer equipment efficiency is basically 30K/H, taking 1.25 as an example, the 8-hour production capacity is only 2 boxes.

Poor consistency: Because the COB small pitch display product is an integrated package chip, and the chip can not be mixed like a single LED, the luminous wavelength is inconsistent. In terms of display consistency, it is weaker than SMD small pitch products.

Poor equipment accuracy: Micron chip, equipment accuracy deviation is too large, resulting in yield can not be improved.

Module color difference: The ink color difference caused by PCB machine difference + colloidal machine ink color deviation, the cumulative finished product will have a large color difference.

High repair cost: a single light source necrosis requires the entire module to be removed and replaced, need to balance the cost of single light source repair and front replacement.

Reflection: Plane module reflection is more serious, matte surface and film effect is better.

High cost: high cost, high input, low production capacity, high raw material cost, finished product price is much higher than SMD, (at this stage, the inversion and formal assembly process is mature, the cost is controllable, and the flip chip is not used on a large scale, the process is continuously improved, the cost is relatively high.) Technical cost investment is high, heavy asset equipment, most of the equipment of downstream display manufacturers are suitable for SMD technology route, the use of COB equipment replacement cost, and the common rate of traditional SMD equipment is less than 10%.

Nowadays, the development of COB packaging technology is becoming more and more mature, and its pain points have been solved by various technical means. For many high-end application scenarios, COB series products will be one of the best choices. Milestrong's three COB products (MCOB Series, UCOB Series, SCOB Sereis) will help you enhance your indoor visuals.

- Previous Article:Anti Counterfeiting Warning

- Next Article:Milestrong Customized Sphere LED Display: A Technological Innovation for Panoramic Presentation