Common Faults and Solutions of COB LED Display Screen

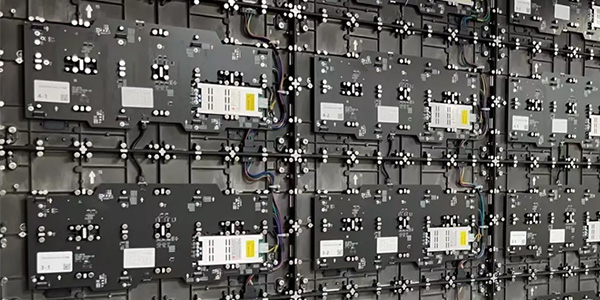

COB LED display screens, with their outstanding display performance, such as high pixel density, wide viewing angles, and excellent protection performance, have been widely applied in numerous scenarios including meeting rooms, exhibition halls, and classrooms. The full flip-chip COB technology involves directly flip-chip onto the PCB board and then forming a module through gel packaging. This process enables the LED to have a larger light-emitting area, higher luminous efficiency, and reduces the gap between chips, thereby enhancing display uniformity and overall brightness. As the LED chip is directly welded to the substrate, the thermal resistance is reduced, heat dissipation is faster, and the lifespan of the display screen is prolonged. During the usage process, users may encounter various problems. Before solving these problems, it is necessary to first understand the key structure and working principle of COB packaging. This is helpful for determining the cause of the fault. The three major parts of the COB display, namely the power drive circuit, signal transmission path and chip body, are interdependent. Any problem can cause different types of faults.

The COB LED display is black

Black screen is usually due to power supply and signal issues. Check if the power supply is normal, ensure that the power cord is connected properly and the power switch is turned on. At the same time, check the signal line connection: Confirm that the sending card, receiving card and signal line connection are correct. You can try restarting the device to restart the sending card and receiving card.

Color blocks and shadows appear on the COB LED display

The screen brightness is uneven, with local areas having significantly higher or lower brightness than other parts. In severe cases, obvious bright or dark spots may form. COB packaging technology is highly challenging, and the technological development of various manufacturers varies greatly. Due to its inability to mix lights, distinguish light and color, and the precision of materials such as chips and manufacturing processing, problems such as uneven brightness and color within the module, color differences between modules, and inconsistent high and low brightness display effects and correction effects occur. First, check the signal source to confirm whether the video signal source is normal. You can replace the signal source. At the same time, check the network cable connection to ensure that the network cable connection between the sending card and the receiving card is stable. Confirm that under normal circumstances, adjust the display parameters: adjust parameters such as brightness, contrast, and color temperature to optimize the display effect. If the problem remains unsolved, you can try to correct the screen.

The COB LED display screen lags when playing videos

Check the video format. It is recommended to use the MP4 format encoded with H.264 to ensure smooth playback. To upgrade the playback device, it is recommended to use a professional player or a high-performance computer. Check if the cables are damaged and optimize the network environment. For video content transmitted over the network, it is recommended to use a wired network connection to ensure transmission stability. Low resolution or frame rate. If the video file is too large, the resolution or frame rate can be appropriately reduced to improve the smoothness of playback.

Abnormal and flickering of single or multiple lamp beads

The core of a fully flip-chip COB display is the LED chip itself. If the chip quality does not meet the standards or the packaging material has defects (such as bubbles or cracks), it is very likely to cause the LED beads to fail. Especially in high-temperature environments, the mismatch of thermal expansion of the packaging material will accelerate the damage to the chip, manifested as insufficient brightness or direct loss of light.

Broken wires or solder joint detachment. Flip-chip technology relies on small area connection points. Once the solder joints are damaged due to transportation, installation or vibration, the current supply will be interrupted, which is manifested as a single lamp bead or part of the lamp beads not lighting up.

Driver IC failure. The driver IC is an important component for controlling the working state of the LED. A failed IC may cause the corresponding area to fail to light up normally or show flickering and abnormal colors. The damage of a driver IC is generally related to overload current, electrostatic discharge or abnormal working environment.

Signal transmission problem. The signal link of the fully inverted COB display is complex. If the data cable interface has poor contact, the cable is damaged or the control card malfunctions, it is easy to cause image loss, screen flickering or abnormal refresh.

COB Product Usage and Maintenance Guide

1. Avoid collision and squeezing

The COB LED display adopts high-density packaging technology, with no exposed LED beads on the surface, and has strong impact resistance. However, it still needs to avoid being hit and squeezed by hard objects to extend its service life.

2. Pay attention to moisture-proofing and dust-proofing

COB products are suitable for a variety of complex environments, but it is still recommended to keep the usage environment dry and clean, and avoid prolonged exposure to damp or dusty conditions.

3. Regular maintenance and servicing

Software upgrade: Regularly update the control system software to obtain the latest functions and performance optimizations.

Hardware inspection: Conduct a comprehensive inspection every six months, including power modules, signal transmission lines, etc., to ensure the stable operation of the equipment.