Comparison between COB LED and Traditional SMD LED

In the field of LED display technology, COB and SMD are two manufacturing processes. At the current stage, the SMD process still dominates, but LED displays produced using the COB process are gradually eroding the market share of SMD as users begin to pursue higher-end, higher-definition, and more durable LED display products.

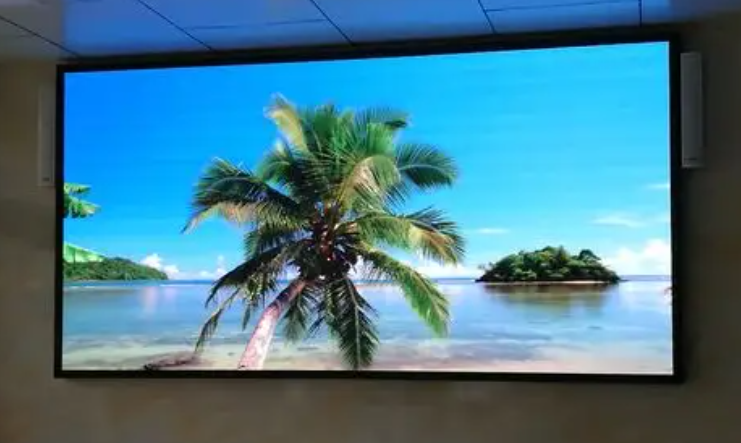

SMD LED Display

Packaging Processes of COB and SMD:

SMD involves individually packaging single chips, while COB uses integrated packaging for multiple chips. The most obvious difference lies in heat dissipation performance—SMD has significantly poorer heat dissipation compared to COB. In SMD, chips are mounted on the PCB board, whereas in COB, they are directly soldered onto the PCB. This gives LED displays produced with the COB process a notable improvement in lifespan.

Energy Efficiency Comparison of COB and SMD:

The reason why COB LED displays are becoming increasingly popular among users is reflected in multiple aspects. COB offers higher brightness, lower power consumption, and reduced light decay due to its excellent heat dissipation. Additionally, the finer LED chips and denser arrangement result in a brighter yet softer display effect.

COB LED Display

Application Fields of COB and SMD:

Traditional SMD-produced LED displays can still meet the needs of most scenarios today. However, COB-produced displays are better suited for high-end venues or environments that demand high-definition image quality, energy efficiency, and are used in important commercial settings.